Capabilities

Providing You With the Best Trenchless Excavation Solutions

Lowe Construction can provide all of the following services:

Boring and Jacking:

This method installs a pipe simultaneously with the excavation process. Here, the operator works at the drive pit or shaft and we can install casing diameters from Ø22" to Ø72" with drive lengths up to 800 Lf depending on soil conditions.

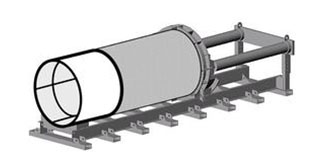

Pipe Jacking:

This method installs a carrier pipe directly into the earth. Pipe examples: Reinforced Concrete Pipe (RCP), Fiberglass Reinforced Pipe (FRP), or Steel Casing. The operator works inside the shield at the face. With this method we can install diameters from Ø36" to Ø96" and we have completed drive lengths up to 1000 Lf depending on soil conditions.

Tunnel Boring Machine (TBM):

This method is similar to pipe jacking and tunneling, but consists of a powered boring head. The operator is positioned inside the tunneling head. With this method, we can install diameters from Ø48" to Ø114" with drive lengths up to 1000 Lf. Longer drives are feasible with intermediate jacking stations.

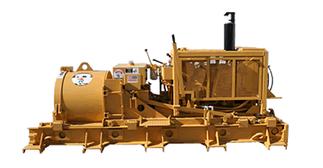

Guided Boring Machine (GBM):

This method installs small diameter pipes with grade and alignment precision. The pipe installation involves a three-step process where launch and reception shafts are strategically located to minimize surface disruption. The process is used in conjunction with a theodolite guidance system to provide accurate pipe installation. installation of pipes in the Ø4" - Ø48" OD range in displaceable soil under 50 blow count.